Title:

Assessment of the Effects of Different Compositions of Ingredients Used

on the Characteristics of an Emulsion Formulation

Objective:

- To determine the effect of HLB surfactant on the emulsion stability.

- To study the effect on physical and stability of the emulsion when the different amount of emulsifying agent have been used.

Introduction:

Emulsion

is a 2 phase systems that thermodynamically not stable. It contains at least 2

immiscible liquid which internal phase distributed homogenously in the other

liquid phase (external phase). Emulsion can be classified into oil in water

emulsion (o/w) and water in oil emulsion (w/o). Emulsion is stabilizing using

the emulsifying agents. The emulsifying agent can be classified into 4 types,

which are hydrophilic colloid, fine solid phase, surface active agent and

surfactant.

The

HLB (hydrophilic-lipophilic balance) have been used to determine the quantity

and the type of surfactant need to be used to prepare a stable emulsion. Every

surfactant has it own HLB range which is from 1 (lipophilic) until 20

(hydrophilic). Normally, the usage of 2 emulsifying agent will form a very

stabilize emulsion preparation. The HLB value can be determine using the

equation below:

HLB

value =

|

[(quantity

of surfactant 1)(HLB of surfactant 1) + (quantity of surfactant 2)

(HLB

of surfactant 2)]

|

quantity of surfactant 1 + quantity of surfactant 2

|

Apparatus:

8 test tubes, measuring cylinder

50ml, pipette, droppers, weighing boat, mortar and pestle,

Light microscope, glass slide,

cover slip, beaker, centrifuge, Coulter Counter machine, Vortex mixture law, viscometer,

water bath (45 degree Celsius), refrigerator (4 degree Celsius).

Materials:

Palm oil, arachis oil, olive oil,

mineral oil, distilled water, span 20, tween 80, Sudan III solution (0.5%) and

ISOTON III solution.

Figure 1: Acacia gum

Figure 2: Span20

Figure 3: Tween 80

Figure 4: Palm Oil

Procedure:

1. 8

tests tube is labeled and 1cm from the bottom is marked at the tests tube.

2.

4mL of oil (refer to table I) and 4ml of distilled

water is mixed in the test tube.

Table I

Group

|

Type of oils

|

1,5

|

Palm oil

|

2,6

|

Arachis oil

|

3,7

|

Olive oil

|

4,8

|

Mineral oil

|

3. Span

20 and Tween 80 is added to the mixture according to the amount given in the

table below. The mixture is mixed using the Vortex mixing machine for about 45

seconds. The time taken for separation to occur until it reaches the 1cm marked

is recorded. The HLB value for each sample is determined.

The mixture is mixed using Vortex mixing machine:

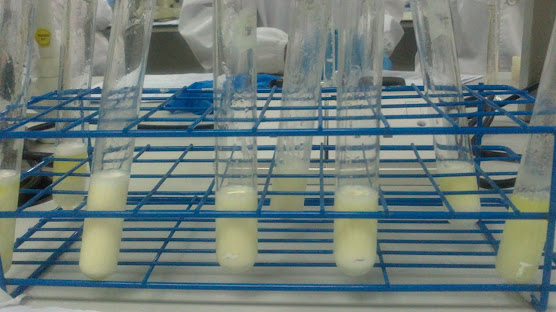

Figure 5: Emulsions with different composition of Span 20 and Tween 80

Table II

Tube no.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

Span 20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

Tween 80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

4. The

Sudan III mixture is dropped into 1g of each of the emulsion produced in the

weighing boats. The color dispersion is described and compared with other

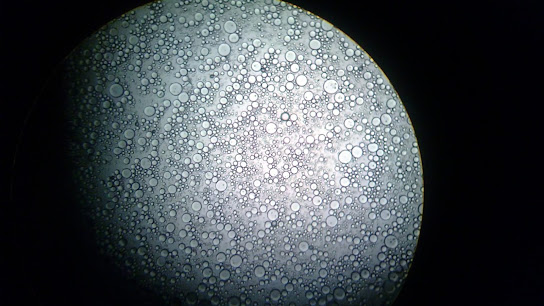

emulsion formulation. The emulsion is observed under the light microscope. The

structure and globule size are determined and drawn to compare with other

emulsion.

Figure 6: Sudan III solution is added to the emulsion

Figure 7: The emulsion is observed under light microscope

5. The Mineral Oil Emulsion (50g) is

prepared using wet gum method following the formulation below:

Mineral

oil

|

Referred

to table III

|

Acacia

|

6.25g

|

Syrup BP

|

5ml

|

Vanillin

|

2g

|

95% Ethanol

|

3ml

|

Distilled water

|

qs. 50ml

|

6. 40g

of the emulsion is placed in a 50ml beaker and homogenize for 2 minute using

homogenizer

7. 2g

of the sample before and after been homogenized is taken out and placed in the

weighing boats. Sudan III solution is dropped into the emulsion. The texture,

consistency, appearance of the oil and the color dispersion is determined and

compared which is it is observed under the light microscope

8. 15g

of the emulsion that have been homogenized is taken and the viscosity is

determined using the viscometer that has been calibrated using the “Spindle”

LV-4 type. The sample is placed at 45°C for about 30 minutes and at 4°C for 30

minutes afterward. The viscosity is determined afterward.

9. 5g

of the emulsion is centrifuged in 4500rpm, for 30 minutes at 25oC. The

separation is measured and the ratio is determined.

Results:

The structure and globule size under light microscope:

Figure 8a: The emulsion in tube 1

Figure 8b: The emulsion in tube 2

Figure 8c: The emulsion in tube 3

Figure 8d: The emulsion in tube 4

Figure 8e: The emulsion in tube 5

Figure 8f: The emulsion in tube 6

Figure 8g: The emulsion in tube 7

Figure 8h: The emulsion in tube 8

Phase Separation and HLB Value:

Tube no.

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Span 20 (drops)

|

15

|

12

|

12

|

6

|

6

|

3

|

0

|

0

|

|

Tween 80 (drops)

|

3

|

6

|

9

|

9

|

15

|

18

|

15

|

0

|

|

HLB Value

|

9.67

|

10.73

|

11.34

|

12.44

|

13.17

|

14.09

|

15.00

|

0

|

|

Time taken for Phase Separation (min)

|

Palm Oil

|

38

|

127

|

123

|

79

|

121

|

126

|

11

|

1

|

Arachis Oil

|

>120

|

>120

|

>120

|

45

|

37

|

18

|

77

|

2

|

|

Olive Oil

|

40

|

>120

|

>120

|

64

|

59

|

21

|

34

|

5

|

|

Mineral Oil

|

>90

|

>90

|

>90

|

>90

|

55

|

47

|

12

|

2

|

|

Stability

|

Palm Oil

|

/

|

/

|

/

|

/

|

/

|

/

|

X

|

X

|

Arachis Oil

|

/

|

/

|

/

|

X

|

X

|

X

|

X

|

X

|

|

Olive Oil

|

X

|

/

|

/

|

X

|

X

|

X

|

X

|

X

|

|

Mineral Oil

|

/

|

/

|

/

|

/

|

X

|

X

|

X

|

X

|

|

Viscosity of emulsion :

Difference

= (Average of after temperature cycle-Average of before temperature cycle )/(Average+SD of before temperature cycle)×100%

At 20 mL of

Mineral Oil :

Readings

|

Group

|

Viscosity

(cP)

|

Average + SD

|

|||

1

|

2

|

3

|

||||

Before temperature cycle

|

1

|

150

|

100

|

150

|

78.33 + 57.57

|

|

5

|

20

|

20

|

30

|

|||

After temperature cycle

|

1

|

200

|

200

|

250

|

114.17+103.86

|

|

5

|

10

|

10

|

15

|

|||

Difference (%)

|

45.76%

|

|||||

At 25 mL of Mineral Oil :

Readings

|

Group

|

Viscosity

(cP)

|

Average + SD

|

|||

1

|

2

|

3

|

||||

Before temperature cycle

|

2

|

30

|

60

|

120

|

60+28.28

|

|

6

|

50

|

50

|

50

|

|||

After temperature cycle

|

2

|

120

|

120

|

90

|

105+11.18

|

|

6

|

100

|

100

|

100

|

|||

Difference (%)

|

75%

|

|||||

At 30 mL of

Mineral Oil :

Readings

|

Group

|

Viscosity

(cP)

|

Average + SD

|

|||

1

|

2

|

3

|

||||

Before temperature cycle

|

3

|

420

|

480

|

540

|

490+46.19

|

|

7

|

450

|

500

|

550

|

|||

After temperature cycle

|

3

|

2800

|

2650

|

2460

|

2626.67+219.97

|

|

7

|

3000

|

2500

|

2350

|

|||

Difference (%)

|

436.06%

|

|||||

For 35 mL of

Mineral Oil :

Readings

|

Group

|

Viscosity

(cP)

|

Average + SD

|

|||

1

|

2

|

3

|

||||

Before temperature cycle

|

4

|

5750

|

5800

|

5850

|

7350+1563.83

|

|

8

|

8900

|

8900

|

8980

|

|||

After temperature cycle

|

4

|

7300

|

7100

|

7200

|

11325+4129.14

|

|

8

|

15650

|

15600

|

15100

|

|||

Difference (%)

|

53.80%

|

|||||

Average viscosity before and after temperature cycle

for different amount of mineral oil

Amount of Mineral Oil (mL)

|

Average Viscosity (cP) (x ± SD)

|

Viscosity difference (%)

|

|

Before temperature cycle

|

After temperature cycle

|

||

20

|

78.33 +

57.57

|

114.17+103.86

|

45.76% ±80.41

|

25

|

60+28.28

|

105+11.18

|

75% ±60.47

|

30

|

490+46.19

|

2176.67+500.89

|

436.06% ±376.23

|

35

|

7350+1550.27

|

11325+4129.14

|

53.80% ±164.04

|

Separation height

Height ratio = (Separation phase )/(Emulsion phase)

Height(mm)

|

|

Seperation Phase

|

29

|

Original Emulsion

|

46

|

Height Ratio

|

29/46 = 0.63

|

Height (mm)

|

||||||||

Group

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

Separation

Phase

|

29

|

35

|

14

|

15

|

40

|

35

|

11

|

11

|

Original

emulsion

|

46

|

55

|

50

|

55

|

50

|

50

|

50

|

50

|

Height

ratio

|

0.63

|

0.64

|

0.28

|

0.27

|

0.8

|

0.70

|

0.22

|

0.22

|

Group 1 and 5 (20ml):-

Group 2 and 4 (25ml):-

Average: 0.715 Average:

0.670

Standard Deviation: 0.120 Standard Deviation: 0.042

Group 3 and 7 (30ml):-

Group 4 and 8 (35ml):-

Average: 0.250 Average: 0.245

Standard Deviation: 0.042 Standard Deviation: 0.035

Mineral oil (ml)

|

Separation phase ratio (x ± SD)

|

20

|

0.715 ± 0.120

|

25

|

0.670 ± 0.042

|

30

|

0.250 ± 0.042

|

35

|

0.245 ± 0.035

|

Discussion:

1) What are the HLB

values that will produce a stable emulsion? Discuss.

HLB System enables us to assign a number to the ingredient or

combination of ingredients we want to emulsify, and then to choose an

emulsifier or blend of emulsifiers having this same number. The HLB value for

the combination of emulsifying agent can be calculated by using this formula:

HLB range

|

Use

|

0-3

|

Anti foaming agents

|

3-6

|

W/O emulsifying agents

|

7-9

|

Wetting and spreading

agents

|

8-18

|

O/W emulsifying agents

|

15-20

|

Solubilisers.

|

The table above contains the range

of the HLB value with the suitable uses. The required HLB for a mixture of

oils, fats and waxes present in a formulation can be calculated theoretically

form the proportion of each component in the oil phase. Usually it is better to

have a mixture of emulsifiers such as oil soluble (low HLB) and a water soluble

(high HLB) surfactant.

2) Compare the physical features of mineral

oil emulsion and give explanation. What is Sudan III Test? Compare dispersion

of color in the emulsion formed and give explanation.

Figure 9: Emulsion added with Sudan III

Before

homogenization, the globules size in the emulsion is not uniform. There are

some big globules and small globules in the emulsion. The size and shape of the

globules is not consistent. Some of the oil globules which are red in color

have bigger circular shape while others are irregular shape red globules.

Besides that the globules are distributed unevenly throughout the emulsion. The

oil globules are unstable with a small size with a large surface area. The

larger the surface area, the larger the surface energy. In order to reduce the

surface energy and to stabilize the emulsion, the small globules tend to

coalesce to become large globules. The emulsion is non homogenous and phase

separation may occur. The oil degree of the emulsion before homogenization is

high and more greasy. The color of the emulsion is yellowish.

After

homogenization, the globules are broken down into smaller one. The globule size

is also more uniform than the emulsion before homogenization. The oil globules

are distributed more evenly. The size and shape of the oil globules are more

consistent. The red color oil globules are circular in shape.

The emulsion is more homogenous and less greasy. The emulsifier is evenly

adsorbed on the interfacial surface of the globules to promote stable emulsion.

Homogenization process is to break down the crystal clump and make the oil

globules more stable in aqueous phase. The homogenized emulsions are white in

color. As the oil globules are evenly distributed, the drugs that are dispersed

inside the oil phase will allow accurate dose dispensed to the patients.

3) Plot and give comments on:

a)

Graph of the sample’s viscosity before and after the temperature cycle against

the variety contents of mineral oil.

Amount of Mineral Oil (mL)

|

Average Viscosity (cP) (x ± SD)

|

Viscosity difference (%)

|

|

Before temperature cycle

|

After temperature cycle

|

||

20

|

78.33 +

57.57

|

45.76% ±80.41

|

|

25

|

60+28.28

|

105+11.18

|

75% ±60.47

|

30

|

490+46.19

|

2176.67+500.89

|

436.06% ±376.23

|

35

|

7350+1550.27

|

11325+4129.14

|

53.80% ±164.04

|

From the graph

above which is obtained based on the results of our experiment, the amount of

oil used influence the viscosity of the emulsion. Besides that the temperature

which the emulsion is stored also has effects on the viscosity of emulsion. The

acacia act as an emulsifying agent which will contribute the viscosity of the

emulsion. But, in this experiment, the amount of acacia used for each group is

the same. Thus, the amount of acacia added will not be studied in this

experiment.

For every

different amount of oil used, the viscosity after the temperature cycle

increased. The emulsion was put in water bath at 450C for 30 minutes

and then freezed at 40C for 30 minutes. Theoretically, the viscosity

of the emulsion after being immersed in the water bath will decrease. This is

because the thermal energy of the droplets and the emulsifying agent at oil in

water interface increased when temperature increase. As temperature increased,

the droplets collide with each other more frequently, interfacial viscosity

decreases and thus the droplets will coalescence more rapidly. In addition, the

solubility of the emulsifying agent increased when temperature increased, the

emulsion is unstable and the viscosity decreased.

The viscosity of

the emulsion increased after the emulsion was freezed. When the temperature

decreased, the kinetic energy of the droplet decreased and the droplets collide

with each other less frequently. Thus, the viscosity of the emulsion increased.

From this graph,

we know that the viscosity difference increases from 20mL of oil to 30mL of

oil. The viscosity increases with the increase of the amount of oil. From 30mL

of oil to 35mL of oil, the viscosity difference decreases. This is because the

emulsion already possesses the highest viscosity in the increase of the amount

of oil.

From the result

obtained from the experiment, the viscosity of the emulsion with 25mL of oil

has the lowest viscosity which is higher than emulsion with 20mL of oil. The

viscosity of emulsion should increase with the increase of the amount of oil

before the amount of dispersed phase exceeds the continuous phase which may

result in phase inversion.

Thus, there may be

some error occurred during the experiment. Error may occur during the

preparation of emulsion. Wet gum method carried out may be failed to get a good

emulsion. Trituration during preparation may not be applied properly. There is

also phase separation of emulsion during the viscosity test which may affect

the reading of the viscometer. Some groups prepared the primary emulsion but

other did not. There are different standard between each groups.

4) Plot a graph of separated phase ratio

formed from the centrifugation process versus the amount of mineral oil used.

Explain.

Mineral oil (ml)

|

Separation phase ratio (x ± SD)

|

20

|

0.715 ± 0.120

|

25

|

0.670 ± 0.042

|

30

|

0.250 ± 0.042

|

35

|

0.245 ± 0.035

|

Phase separation ratio

is used to indicate stability of an emulsion. A high ratio of phase separation

represents an unstable emulsion where two separated phases can be observed. Due

to unstable emulsion, uniformity of drug in the emulsion will be greatly altered

and the accuracy of dose being administered into patient might affected.

Based on the graph plotted, separated phase

ratio decreases from 20mL palm oil emulsion to 25mL arachis oil emulsion,

decreases from 25mL arachis oil emulsion to 30mL olive oil emulsion and

decreases also from 30mL olive oil emulsion to 35mL mineral oil emulsion.

According to theory, the

separation phase ratio should increase with the increasing of the mineral oil

contained in the formulation. This

is because the added amount of oil in emulsion has exceeded the oil amount at

which a stable emulsion can be formed.

Phase separation will occur at a faster rate.

However, the results we obtained from the

experiment do not follow this theory. This may be due to several errors that

occurred during experiment. This may due to some experimental errors

such as measurement mistakes and systemic error. The experimental errors

include inaccuracy in

measuring the amount of oil before forming the emulsion, insufficient

homogenisation that has been carried out on emulsion and the height of

separated phase is not being measured accurately.

Thus, an

appropriate amount of oil should be used in the emulsion to prevent phase

separation as the amount of oil affects the uniformity and stability of the

dose of drug administered. The drug particles should be dispersed in the

emulsion uniformly in an ideal emulsion.

5) What is the function of each material used in the preparation of

this emulsion? How the usage of the different materials content will affect the

physical properties and stability of an emulsion formulation?

Palm oil, arachis oil, olive oil

and mineral oil act as oily phase in the emulsion. It is either dispersed phase

or continuous phase depends on the type of emulsion formed in which it is the

dispersed phase in o/w emulsion and vice versa. In this case, the

mineral oil used in the formulation acts as the dispersed phase while the

distilled water is the continuous phase. Thus, this is a oil in water (o/w)

emulsion. Acacia is added in this formulation which act as emulsifying agent in

order to reduce the surface tension at the interphase surface. Thus, the

mineral oil globules can disperse uniformly in the continuous phase and any

instability of emulsion such as flocculation and creaming or breaking or

coalescence won’t occur. Other instabilities of emulsion include Ostwald

ripening, phase inversion and any miscellaneous physicochemical changes such as

appearance, odour and colour.

As for your

information, emulsifying agents have to be added in the correct amount based on

HLB value. The amount of the acacia added will determine the uniformity of oily droplets

dispersed throughout the emulsion.. If the acacia that added is in adequate

amount, then the oily phase will disperse uniformly in the continuous phase.

However, if either too many or too less acacia is added, the stability of the

emulsion will greatly decrease. Besides maintaining separation of droplets in

disperse phase, it also increases the viscosity of the emulsion formed. As acacia is a natural

polysaccharides and susceptible to microbial attack, thus alcohol is added into

emulsion as preservative to prevent microbial growth. Physicochemical

properties can be enhanced with the addition of alcohol. However, only appropriate amount of alcohol

can be added into emulsion to give greatest antimicrobial effect and prevent

toxicity.

Besides, syrup and

vanillin which act as the sweetener and flavouring respectively are added in

this formulation. Syrup also can increase the viscosity of the emulsion formed.

Amount of turpentine oil

(dispersed phase) and distilled water (continuous phase) added to form an

emulsion is important in determining the type and stability of emulsion formed.

The volume of dispersed phase should not be more than the volume of the

continuous phase. The stability of emulsion formed will decrease if the volume

of dispersed phase exceeds 50% of the emulsion. Phase inversion tends to occur

for emulsions containing more than about 70% dispersed phase.

Conclusion:

Low HLB surfactant

value, 3-9 is suitable to be used in water in oil emulsion. While, the high

value of HLB surfactant, 8-18 is suitable for the formation of oil in water

emulsion. Combination of surfactants, such as Span and Tween will form a more

stable emulsion than a single surfactant. Different oily phase need a different

value of HLB surfactant so that the most stable emulsion can be formed. The physical and stability of the

emulsions are different if the amount of emulsifying agent used is different.

References :

- Pharmaceutical

Practice, A.J. Winfield, J.A. Rees, I.Smith, 4th edition

- Composition

And Properties Of Drilling And Completion Fluid, R.Caenn, G.R. Grey,

H.C.H. Darley, 6th edition

No comments:

Post a Comment